Here’s what it takes to make an exhaust duct joint on FRP Duct

Joints on FRP duct are traditionally accomplished by means of a labor intense "butt and wrap" procedure. Duct ends are ground smooth, exposed ends are sealed with catalyzed resin, and the duct or fitting is "buttered-up" and overlaid with several layers of resin and reinforcing fiberglass.

Adhesive curing at an ambient temperature of 70°F would take at least 24 hours to complete, so electric heating blankets are often required to accelerate the time to cure each joint.

Read More

Topics: frp duct, fume exhaust duct, duct installation

5 Advantages of A PSP® Fume Exhaust Duct Installation

Today, savvy wastewater treatment plant owners, engineers, and managers are paying close attention to the potential risks and unforeseen costs of the materials that are being used in their facilities and systems.

One area where material consideration can have both immediate and long lasting impacts is in the odor control systems of a wastewater treatment plant.

When it comes to exhaust duct installation, some materials like FRP duct may require a deep investment of time, money, and specialized labor.

Read More

Topics: frp duct, wastewater treatment plant odor control

Wet scrubber Systems and lab Fume Exhaust

Laboratories are becoming increasingly necessary as more and more products require the controlled conditions that only labs can provide. For the purposes of advanced manufacturing, every process from research, to testing, to development, to cleaning must be conducted with precision and accuracy.

Within these environments, lab fume hoods serve as an integral safety feature to help maintain facility air quality. While fume hoods are typically the first line of defense against hazardous vapors in these settings, they're by no means the only defense.

Read More

Topics: vent duct, research lab safety

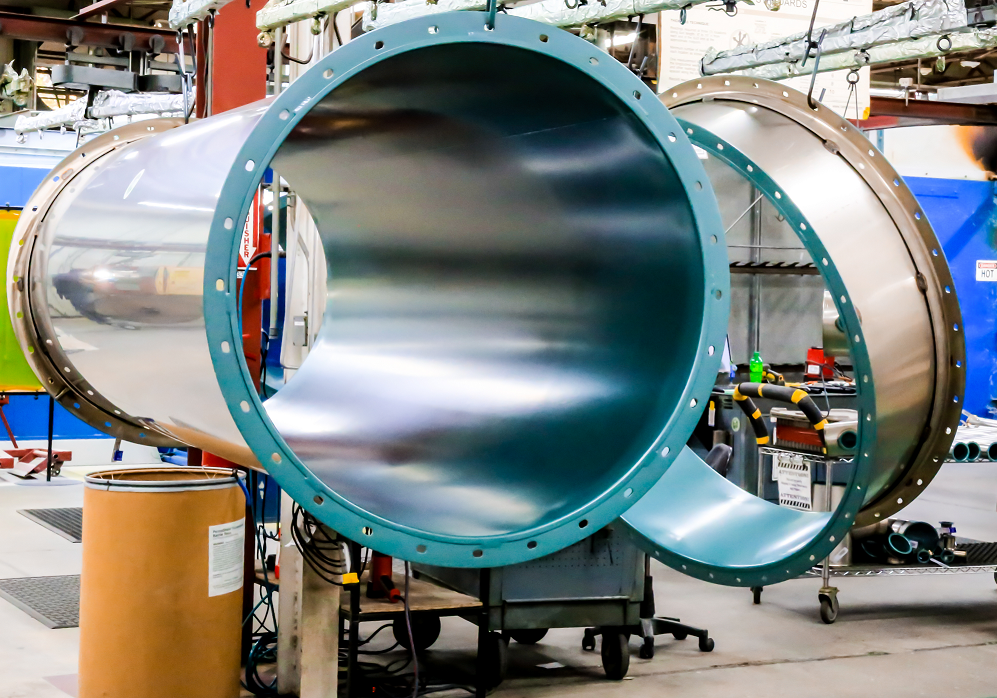

Fluoropolymer Coating and Stainless Steel Fume Exhaust Duct Are a Perfect Combination

There's no shortage of corrosive fumes and vapors generated by process industries which need to be safely and successfully vented.

Common exhaust duct materials that are tasked with this responsibility include stainless steel, polyvinyl chloride (PVC), and fiberglass reinforced plastic (FRP). While special glass linings, metal alloys, and a wide range of polymers may be used individually or in combination to help meet particular demands, none seem to solve the breadth of corrosive application challenges like PermaShield Pipe (PSP®) with its proprietary fluoropolymer coating.

Read More

Topics: fluoropolymer coating, fume exhaust duct

5 Fundamentals For Dynamic Lab Air Quality Needs

In the face of exponentially changing technology and consumer demands, advanced manufacturing industries are driving research labs and clean rooms to accommodate multiple production flows.

As such, these facilities must contend with a wider spectrum of lab air quality requirements, including increased air supply, dynamic airflow patterns, room pressurization, and high-efficiency air filtration versus that of traditional labs and clean rooms.

Here we'll cover 5 fundamental lab air quality considerations that should be factored into every advanced manufacturing clean room or research lab design.

Read More

Topics: lab design, research lab, lab air

Hot Tap Installation Using a Pressurized Glove Box

We all know that change is the only constant. Therefore, it stands to reason that process systems should be designed with adaptability and the eventuality of change in mind. As process intensive facilities grow, there usually comes a time when air-handling and fume exhaust systems need to be expanded or adapted to meet operational demands.

Fortunately, hot tapping with PSP® is a versatile solution that allows users to retro-fit new PSP® components to a variety of host duct systems without costly, time consuming, or disruptive shutdowns to the system.

This instructional demonstrates the relative ease and simplicity with which a hot tap installation can be performed with a zero-leak glove box on PSP® fume exhaust duct.

Read More

Topics: fume exhaust duct, hot tap installation

Hot Tap Installation Without A Pressurized Glove Box

As process systems and facilities grow, there usually comes a time when new fume exhaust components need to be added to existing vent duct configurations.

For most facilities, it can be extremely costly and disruptive to take systems offline in order to make such upgrades. Fortunately, PSP® exhaust duct systems are capable of remaining in-service (hot) while saddle tap installation procedures are performed.

The instructional below focuses specifically on how to perform a hot tap installation on PSP® fume exhaust duct without the use of a glove box. For hot tap installations using a pressurized glove box, please follow this link.

Read More

Topics: vent pipe installation, saddle tap

Why WWTP Owners Prefer PSP® Coated Metal Duct On Their Odor Control Systems

Wastewater treatment plants are sites where odorous and hazardous fumes are dealt with on a daily basis. As facilities face an ever growing list of water and air-quality issues with which to contend, advancements in vapor phase odor control technology have been sought to help mitigate many of these challenges and concerns.

This article examines some of the leading reasons why PSP® fluoropolymer coated stainless steel duct stands out as the preferred choice for wastewater odor control systems.

Read More

Topics: wastewater treatment, frp duct, wastewater treatment plant odor control

10 Benefits of Coated Metal Duct for Wastewater Odor Control Systems

Wastewater odor control systems and vent pipe products not only need to contain foul air but also need to be highly corrosion resistant. For decades, wastewater treatment facility owners (and engineers) have faced a major pain point with plastic and FRP duct systems that degrade and need regular repair or replacement.

Compounding this pain is the fact that many plastic and FRP duct products are highly combustible. In the event of a fire, or gaseous ignition, such systems will likely be rendered useless if not completely destroyed. In short, wastewater facilities with these types of systems face the pain of higher fire insurance premiums; and those that self-insure face catastrophic losses.

Read More

Topics: frp duct, fume exhaust duct, wastewater treatment plant odor control

OSHA AND Lab Safety Standard 29 CFR 1910.1450

Research laboratories are vital to the advancement of technology in many industries including semiconductor, pharmaceutical, chemical, fiber optics, and nanotechnology, to name a few.

In the United States alone, more than a half a million people work in laboratory settings and are faced with the potential dangers that come with this line of employment.

Read More

Topics: fume exhaust duct

4 More Reasons to Use PSP® Coated Metal Duct

It's always nice to discover that little advantage or edge-up which makes our lives easier, safer, cheaper, or more productive. It's even better when that advantage is not so little, and when it improves our lives across all categories!

This article takes aim at four big advantages of PSP® coated stainless steel duct and how it surpasses FRP duct in quality, safety, cost, and convenience.

Read More

Topics: frp duct, wastewater treatment plant odor control

Not All Class 1 Duct is Created Equal

Building codes and regulations stress lower flame spread and low smoke generation for many materials. The Steiner Tunnel Test (ASTM E-84) is frequently referenced as a method to assess these burn characteristics and is a mandatory test for many commercial building materials.

While such standards and mandatory tests are indeed important, it is also critically important to understand their parameters and tolerances.

Read More

Topics: Permashield Pipe, frp duct

Fluoropolymer Coating - Q&A

What is a fluoropolymer? A fluoropolymer is a fluorocarbon-based substance that contains atoms of fluorine. It is characterized by a high resistance to solvents, acids, and bases. Fluoropolymers were discovered by happen-stance in 1938 by Dr. Roy J. Plunkett as he was working on freon (for the DuPont corporation) and accidentally polymerized tetrafluoroethylene.

The result was PTFE (polytetrafluoroethylene), more commonly known as Teflon. This material was found to have the lowest coefficient of friction of any known solid and was inert to virtually all chemicals known. Its corrosion resistivity (in almost all applications) exceeds that of glass (borosilicate and enameled glass-steel) and exotic alloys such as Hastelloy, Niobium, Tantalum and Titanium.

Read More

Topics: coated stainless steel, fluoropolymer coating

5 Things You Should Know Before Using FRP Duct

When it comes to installing odor control systems in wastewater treatment facilities, one of the many design considerations to resolve is whether to use fiberglass reinforced plastic (FRP) or coated stainless steel duct.

Historically, FRP duct has been the more common choice from a cost perspective, but increasingly savvy WWTP owners and engineers are recognizing that there are hidden costs and strict rules and regulations that come with a decision to use FRP materials.

Read More

Topics: frp duct, wastewater treatment plant odor control

Leading wastewater treatment facilities ARE Using PermaShield Pipe

Many modern wastewater treatment facilities are moving away from traditional fiberglass reinforced plastic (FRP duct) and employing PSP® odor control exhaust duct instead. Through informed research, facility owners and engineers are learning that PSP® delivers superior performance, superior labor savings, superior safety, and lower maintenance than FRP duct.

Read More

Topics: frp duct, fume exhaust duct, wastewater treatment plant odor control

More Reasons To USE Fluoropolymer Coated Stainless Steel Over FRP Duct

When it comes to corrosive fume exhaust systems, process facilities must ensure that their equipment and practices adhere to strict regulatory standards all while remaining as flexible as possible to adapt to future mandates and regulation changes.

In the midst of this balancing act, facility owners and engineers are finding PSP® fluoropolymer coated stainless steel to be a more versatile, affordable, compliant, durable and safe alternative to fiber-glass reinforced plastic (FRP duct).

Read More

Topics: frp duct

4" - 14" PSP-EZ Duct Installation

Time is money, and when you're in the midst of a vent duct installation or overhaul, reductions in installation time can have a significant impact on the total cost and ROI of your project.

Fab-Tech's PermaShield Pipe (PSP®) is already known to reduce installation labor by a significant margin, but there's an even faster and easier installation option that's available for those who specify PSP-EZ™ duct.

When you specify PSP-EZ™ for a system joint, a single fastener and band-style clamp configuration is employed in place of companion angle rings with multiple fasteners. The EZ-Clamp joining mechanism provides safe, reliable joints without sacrificing system flexibility or integrity.

Read More

Topics: PSP-EZ duct installation

How To Join Psp® To DisSimilar Materials Like FRP Duct

There are many process facilities that require specialty exhaust duct systems to handle their process fume exhaust. Where a facility is expanding or a section of vent duct needs to be replaced, it is often the case that customers would like to upgrade to FabTech's PSP® to replace weathered and corroded components in their non-PermaShield system.

To put to rest any notion that this presents some kind of engineering challenge, this brief article demonstrates the ease and compatibility with which PermaShield Pipe can be connected to dissimilar materials like FRP duct.

Read More

Topics: frp duct, fume exhaust duct

Urban Growth Projections and wastewater Treatment Odor Control Implications

Over the next 6 years, the global market for wastewater treatment equipment and chemical products is expected to grow by more than 138 billion dollars (1). This enormous increase in spending will be driven by shrinking clean water supplies, increasing demand, growing population densities, and the growth of industrial applications beyond current water treatment capacities.

Read More

Topics: wastewater odor control, wastewater treatment plant odor control

PSP® Vent Pipe USed In Multiple Wastewater Odor Control Areas at DC Blue Plains

The DC Water and Sewer Authority (Blue Plains) is the largest wastewater treatment facility in the world. DC Water utilizes some of the most advanced treatment systems available to provide water and wastewater treatment services to more than 600,000 local residents, another 1.6 million people from neighboring Maryland and Virginia, 17.8 million annual visitors and 700,000 people that work in the DC area.

Read More

Topics: vent pipe, biosolids management, wastewater treatment plant odor control

/Positioning%20hot%20tap.png)

/Saddle%20tap%20installed%20on%20PSP%20coated%20vent%20pipe.png)

/odor%20control%20vent%20pipe%20at%20brightwater%20wwtp.png)

/Research%20labs%20and%20lab%20safety%20measures.png)

/PSP%20coated%20stainless%20steel%20duct.png)

/class%201%20duct%20fire%20safety.png)

/question-mark.png)

/Fluoropolymer%20coated%20stainless%20steel%20application.png)

/Brightwater%20WWTP%20advanced%20wastewater%20treatment%20technologies.png)

/FRP%20duct%20fire%20at%20wastewater%20treatment%20facility.png)

/PSP-EZ%20Duct%20Installation-Strength.png)

/PSP%20and%20frp%20duct%20at%20Brightwater%20WWTP.png)

/Urbanization%20and%20wastewater%20treatment%20implications.png)

/PermaShield%20vent%20pipe%20installed%20at%20biosolids%20management%20facility.jpg)