Improving Facility Safety With PSP Fume Exhaust Duct

When it comes to industrial facility processes, there's no question that specific safety protocols can help mitigate the risks and hazards that are inherent in these environments. But workplace safety can, and should, extend beyond prudent practices to include fully engineered solutions that are part of the process facility equipment and infrastructure.

Read More

Topics: fume exhaust duct, industrial facility safety

Sandia National Laboratories Bldg. 858N SW Acid Exhaust

A recent acid exhaust project where we supplied our PSP® to JB Henderson for an installation at Sandia National Labs was recognized for "outstanding specialty work" in an occupied and operational facility.

The project called for more than 2,000 linear feet of PSP fluoropolymer coated stainless steel duct to replace the existing weathered and contaminated FRP duct system.

Read More

Topics: fume exhaust duct, acid fumes, acid exhaust

PSP® Coated Metal Fume Exhaust Duct Excels Across Industries

Operational demands and safety requirements have driven a clear need for more chemically resistant and fire resistant fume exhaust systems among advanced process facilities. Exhaust duct systems in these environments must be able to chemically withstand highly corrosive process fume exhaust, not contribute to smoke or flame-spread in the event of a fire, and still stand up to any external environmental conditions or aggressive cleaning agents to which they may be exposed over the course of their lifecycle.

Read More

Topics: fume exhaust duct, lab safety

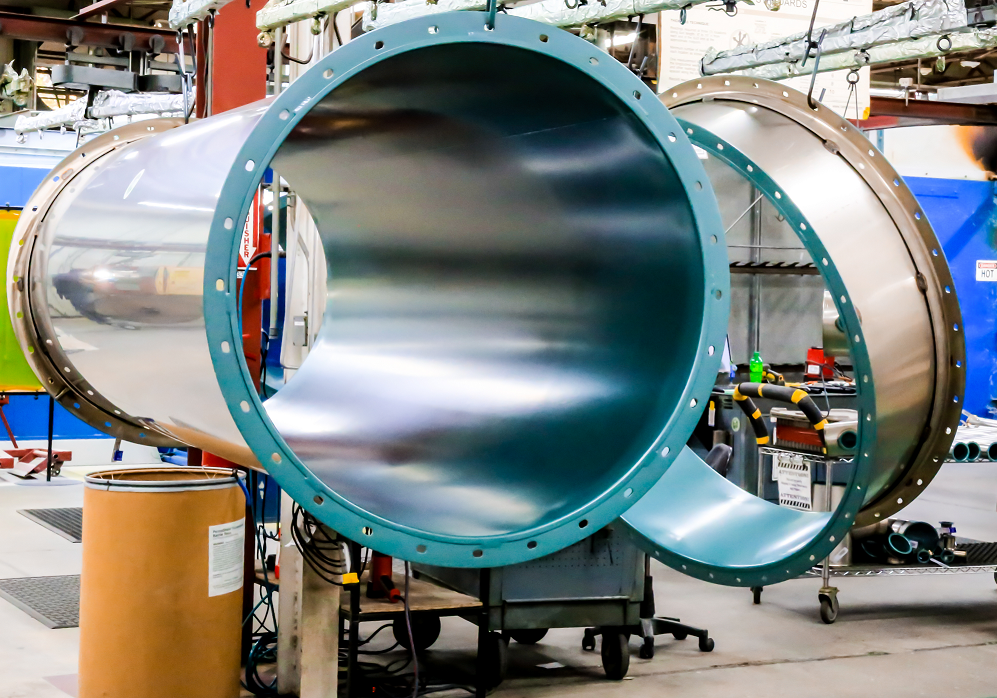

Merging Size and Safety in PSP® Fume Exhaust Duct Production

As part of a corporate wide safety awareness initiative, Fab-Tech recently implemented changes to our manufacturing process to reflect a safer way to perform the fabrication and coating of our vent duct systems. Since our largest diameter exhaust duct was among the first to roll off the production line following the process updates, we decided it was time to take a step back and admire the fruits of our labor.

Read More

Topics: fume exhaust duct, careers

Why Lab Ventilation Systems Should Use PSP® Fume Exhaust Duct

Fab-Tech’s proprietary fluoropolymer coated stainless steel fume exhaust duct carries clear benefits across an array of industrial and scientific research applications.

Given its status as the material of choice for venting corrosive fumes in semiconductor manufacturing, laboratory owners in private and university settings have taken note and are now following suit.

Read More

Topics: frp duct, fume exhaust duct, laboratory ventilation

PSP® Enhances lab Safety in State Of The Art MIT Nano-Complex

MIT is currently constructing a 200,000 square foot center for nanotechnology and nano-science at their campus in Cambridge, MA. Nicknamed MIT.nano, the facility will follow an open lab design concept to bring faculty, researchers and students together on a grand scale of collaboration.

Read More

Topics: fume exhaust duct, lab design, lab safety

Fume Hood Safety Protocols Should Be In Lockstep with a Safe Lab Design

Fume hoods serve as the literal and figurative birthplace for next generation research and scientific discovery. Within these clean, confined spaces, our world is discovering new ways to improve the quality of life for all.

Thomas Edison was known to utilize his fireplace chimney as a fume vent. Without it, chances are his work would have ended prematurely.

These days, fume hoods are better ventilated, more chemically resistant, cleaner, and perform better than Edison’s fireplace, but they still require basic care and planning to ensure that lab safety is not compromised.

Read More

Topics: fume exhaust duct, lab design, lab safety

Here’s what it takes to make an exhaust duct joint on FRP Duct

Joints on FRP duct are traditionally accomplished by means of a labor intense "butt and wrap" procedure. Duct ends are ground smooth, exposed ends are sealed with catalyzed resin, and the duct or fitting is "buttered-up" and overlaid with several layers of resin and reinforcing fiberglass.

Adhesive curing at an ambient temperature of 70°F would take at least 24 hours to complete, so electric heating blankets are often required to accelerate the time to cure each joint.

Read More

Topics: frp duct, fume exhaust duct, duct installation

Fluoropolymer Coating and Stainless Steel Fume Exhaust Duct Are a Perfect Combination

There's no shortage of corrosive fumes and vapors generated by process industries which need to be safely and successfully vented.

Common exhaust duct materials that are tasked with this responsibility include stainless steel, polyvinyl chloride (PVC), and fiberglass reinforced plastic (FRP). While special glass linings, metal alloys, and a wide range of polymers may be used individually or in combination to help meet particular demands, none seem to solve the breadth of corrosive application challenges like PermaShield Pipe (PSP®) with its proprietary fluoropolymer coating.

Read More

Topics: fluoropolymer coating, fume exhaust duct

Hot Tap Installation Using a Pressurized Glove Box

We all know that change is the only constant. Therefore, it stands to reason that process systems should be designed with adaptability and the eventuality of change in mind. As process intensive facilities grow, there usually comes a time when air-handling and fume exhaust systems need to be expanded or adapted to meet operational demands.

Fortunately, hot tapping with PSP® is a versatile solution that allows users to retro-fit new PSP® components to a variety of host duct systems without costly, time consuming, or disruptive shutdowns to the system.

This instructional demonstrates the relative ease and simplicity with which a hot tap installation can be performed with a zero-leak glove box on PSP® fume exhaust duct.

Read More

Topics: fume exhaust duct, hot tap installation

10 Benefits of Coated Metal Duct for Wastewater Odor Control Systems

Wastewater odor control systems and vent pipe products not only need to contain foul air but also need to be highly corrosion resistant. For decades, wastewater treatment facility owners (and engineers) have faced a major pain point with plastic and FRP duct systems that degrade and need regular repair or replacement.

Compounding this pain is the fact that many plastic and FRP duct products are highly combustible. In the event of a fire, or gaseous ignition, such systems will likely be rendered useless if not completely destroyed. In short, wastewater facilities with these types of systems face the pain of higher fire insurance premiums; and those that self-insure face catastrophic losses.

Read More

Topics: frp duct, fume exhaust duct, wastewater treatment plant odor control

OSHA AND Lab Safety Standard 29 CFR 1910.1450

Research laboratories are vital to the advancement of technology in many industries including semiconductor, pharmaceutical, chemical, fiber optics, and nanotechnology, to name a few.

In the United States alone, more than a half a million people work in laboratory settings and are faced with the potential dangers that come with this line of employment.

Read More

Topics: fume exhaust duct

Leading wastewater treatment facilities ARE Using PermaShield Pipe

Many modern wastewater treatment facilities are moving away from traditional fiberglass reinforced plastic (FRP duct) and employing PSP® odor control exhaust duct instead. Through informed research, facility owners and engineers are learning that PSP® delivers superior performance, superior labor savings, superior safety, and lower maintenance than FRP duct.

Read More

Topics: frp duct, fume exhaust duct, wastewater treatment plant odor control

How To Join Psp® To DisSimilar Materials Like FRP Duct

There are many process facilities that require specialty exhaust duct systems to handle their process fume exhaust. Where a facility is expanding or a section of vent duct needs to be replaced, it is often the case that customers would like to upgrade to FabTech's PSP® to replace weathered and corroded components in their non-PermaShield system.

To put to rest any notion that this presents some kind of engineering challenge, this brief article demonstrates the ease and compatibility with which PermaShield Pipe can be connected to dissimilar materials like FRP duct.

Read More

Topics: frp duct, fume exhaust duct

How To Properly Store and Handle PSP® FUME Exhaust Duct For Optimal Performance

Proper shipping and handling of PSP® fume exhaust duct is essential for successful installation and optimal performance. Because its interior surfaces are protected with a revolutionary fluoropolymer barrier coating, proper care must be taken to protect this coating from being damaged during shipping, moving, and installation.

The guidelines below will help to ensure that your PSP® fume exhaust duct will serve its lifetime intended purpose; far outlasting any other corrosive fume handling products out there.

Read More

Topics: fume exhaust duct

PSP® Fume Exhaust Duct Provides Solution For Renowned SUNY Nanotech complex

Nanotechnology is not only a rapidly advancing field of study, but a broadening commercial opportunity as well. The ability to observe and manipulate materials at nanoscale, literally at the atomic level, is opening up whole new fields of science and engineering.

Read More

Topics: fume exhaust duct, research lab safety, semiconductor manufacturing

/Baldwinsville%20Knolls%20WWTP%20Sept%202022%20-%2084.jpg)

/psp-fume-exhaust-duct-systems.png)

/FTI-first-120-inch-fume-exhaust-duct.png)

/research%20lab%20fume%20exhaust%20duct.png)

/MIT%20clean%20room%20PSP%20exhaust%20duct%20system.png)

/Lab%20fume%20hood%20experiment.png)

/Positioning%20hot%20tap.png)

/Research%20labs%20and%20lab%20safety%20measures.png)

/Brightwater%20WWTP%20advanced%20wastewater%20treatment%20technologies.png)

/PSP%20and%20frp%20duct%20at%20Brightwater%20WWTP.png)

/Fluoropolymer%20coated%20stainless%20steel%20vent%20pipe%202.png)