An Assessment of Landfilled GFRP Composite Waste

As communities, municipalities and wastewater treatment facilities alike devote more and more resources toward mitigating hydrogen sulfide gas (H2S) as an industrial and environmental pollutant [1], the resultant foul-air systems and the materials from which they are constructed must be called into question.

Read More

Topics: frp duct, wastewater treatment plant odor control

Coated Stainless Steel versus FRP Duct On Sustainability

We are entering a new age, one where people are realizing that it’s possible to meet and exceed business financial goals and to still make progress in preserving our environment. This concept is taking hold in new and diverse ways across many commercial and industrial spheres. It's known as the circular economy.

You’ll be hearing this phrase more and more as its influence grows, but what exactly does it mean?

Read More

Topics: frp duct, wastewater treatment plant odor control

Why Lab Ventilation Systems Should Use PSP® Fume Exhaust Duct

Fab-Tech’s proprietary fluoropolymer coated stainless steel fume exhaust duct carries clear benefits across an array of industrial and scientific research applications.

Given its status as the material of choice for venting corrosive fumes in semiconductor manufacturing, laboratory owners in private and university settings have taken note and are now following suit.

Read More

Topics: frp duct, fume exhaust duct, laboratory ventilation

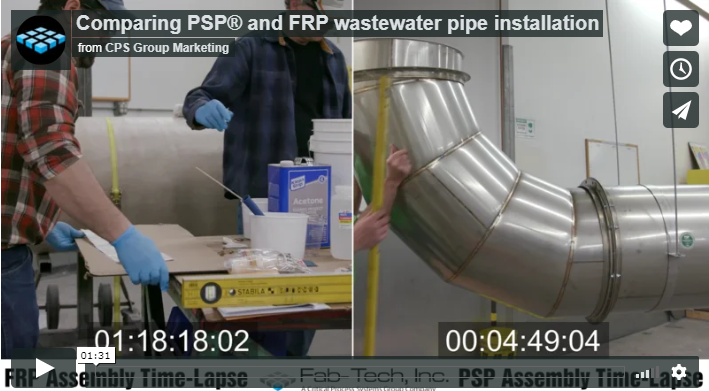

Video Comparison of PSP® Vent Pipe and FRP Duct Assembly

A common belief among engineers and facility designers is that coated stainless steel vent pipe is more expensive than FRP duct alternatives. While the upfront material costs of fiberglass may appear slightly cheaper on estimates, it is most important to compare equivalent systems, such as the resin and service type of FRP duct, and to include an evaluation of system installation time and cost.

Read More

Topics: vent pipe installation, frp duct, duct installation

A Closer Look At The Class 1 Fire Rating And ASTM E-84 Results of PSP® Fume Exhaust Duct

Prior to the appearance of 300 series fluoropolymer coated stainless steel, the most common materials for process ventilation were galvanized steel, polyvinyl chloride, polypropylene and FRP duct.

In today's high-cost high-tech process facilities, strong regulations and higher standards for fire-safety are turning the attention of facility owners, engineers, and underwriting insurers alike toward PSP® fluoropolymer coated fume exhaust duct.

To understand why, let's take a look at how PSP® gets its superior Class 1 fire rating.

Read More

Topics: frp duct, class 1 fire rating, astm e-84, class 1 duct

Here’s what it takes to make an exhaust duct joint on FRP Duct

Joints on FRP duct are traditionally accomplished by means of a labor intense "butt and wrap" procedure. Duct ends are ground smooth, exposed ends are sealed with catalyzed resin, and the duct or fitting is "buttered-up" and overlaid with several layers of resin and reinforcing fiberglass.

Adhesive curing at an ambient temperature of 70°F would take at least 24 hours to complete, so electric heating blankets are often required to accelerate the time to cure each joint.

Read More

Topics: frp duct, fume exhaust duct, duct installation

5 Advantages of A PSP® Fume Exhaust Duct Installation

Today, savvy wastewater treatment plant owners, engineers, and managers are paying close attention to the potential risks and unforeseen costs of the materials that are being used in their facilities and systems.

One area where material consideration can have both immediate and long lasting impacts is in the odor control systems of a wastewater treatment plant.

When it comes to exhaust duct installation, some materials like FRP duct may require a deep investment of time, money, and specialized labor.

Read More

Topics: frp duct, wastewater treatment plant odor control

Why WWTP Owners Prefer PSP® Coated Metal Duct On Their Odor Control Systems

Wastewater treatment plants are sites where odorous and hazardous fumes are dealt with on a daily basis. As facilities face an ever growing list of water and air-quality issues with which to contend, advancements in vapor phase odor control technology have been sought to help mitigate many of these challenges and concerns.

This article examines some of the leading reasons why PSP® fluoropolymer coated stainless steel duct stands out as the preferred choice for wastewater odor control systems.

Read More

Topics: wastewater treatment, frp duct, wastewater treatment plant odor control

10 Benefits of Coated Metal Duct for Wastewater Odor Control Systems

Wastewater odor control systems and vent pipe products not only need to contain foul air but also need to be highly corrosion resistant. For decades, wastewater treatment facility owners (and engineers) have faced a major pain point with plastic and FRP duct systems that degrade and need regular repair or replacement.

Compounding this pain is the fact that many plastic and FRP duct products are highly combustible. In the event of a fire, or gaseous ignition, such systems will likely be rendered useless if not completely destroyed. In short, wastewater facilities with these types of systems face the pain of higher fire insurance premiums; and those that self-insure face catastrophic losses.

Read More

Topics: frp duct, fume exhaust duct, wastewater treatment plant odor control

4 More Reasons to Use PSP® Coated Metal Duct

It's always nice to discover that little advantage or edge-up which makes our lives easier, safer, cheaper, or more productive. It's even better when that advantage is not so little, and when it improves our lives across all categories!

This article takes aim at four big advantages of PSP® coated stainless steel duct and how it surpasses FRP duct in quality, safety, cost, and convenience.

Read More

Topics: frp duct, wastewater treatment plant odor control

Not All Class 1 Duct is Created Equal

Building codes and regulations stress lower flame spread and low smoke generation for many materials. The Steiner Tunnel Test (ASTM E-84) is frequently referenced as a method to assess these burn characteristics and is a mandatory test for many commercial building materials.

While such standards and mandatory tests are indeed important, it is also critically important to understand their parameters and tolerances.

Read More

Topics: Permashield Pipe, frp duct

5 Things You Should Know Before Using FRP Duct

When it comes to installing odor control systems in wastewater treatment facilities, one of the many design considerations to resolve is whether to use fiberglass reinforced plastic (FRP) or coated stainless steel duct.

Historically, FRP duct has been the more common choice from a cost perspective, but increasingly savvy WWTP owners and engineers are recognizing that there are hidden costs and strict rules and regulations that come with a decision to use FRP materials.

Read More

Topics: frp duct, wastewater treatment plant odor control

Leading wastewater treatment facilities ARE Using PermaShield Pipe

Many modern wastewater treatment facilities are moving away from traditional fiberglass reinforced plastic (FRP duct) and employing PSP® odor control exhaust duct instead. Through informed research, facility owners and engineers are learning that PSP® delivers superior performance, superior labor savings, superior safety, and lower maintenance than FRP duct.

Read More

Topics: frp duct, fume exhaust duct, wastewater treatment plant odor control

More Reasons To USE Fluoropolymer Coated Stainless Steel Over FRP Duct

When it comes to corrosive fume exhaust systems, process facilities must ensure that their equipment and practices adhere to strict regulatory standards all while remaining as flexible as possible to adapt to future mandates and regulation changes.

In the midst of this balancing act, facility owners and engineers are finding PSP® fluoropolymer coated stainless steel to be a more versatile, affordable, compliant, durable and safe alternative to fiber-glass reinforced plastic (FRP duct).

Read More

Topics: frp duct

How To Join Psp® To DisSimilar Materials Like FRP Duct

There are many process facilities that require specialty exhaust duct systems to handle their process fume exhaust. Where a facility is expanding or a section of vent duct needs to be replaced, it is often the case that customers would like to upgrade to FabTech's PSP® to replace weathered and corroded components in their non-PermaShield system.

To put to rest any notion that this presents some kind of engineering challenge, this brief article demonstrates the ease and compatibility with which PermaShield Pipe can be connected to dissimilar materials like FRP duct.

Read More

Topics: frp duct, fume exhaust duct

/wastewater-treatment-plant-circular-economy.jpg)

/research%20lab%20fume%20exhaust%20duct.png)

/MIT%20clean%20room%20PSP%20overhead%20exhast%20duct%20system.png)

/odor%20control%20vent%20pipe%20at%20brightwater%20wwtp.png)

/PSP%20coated%20stainless%20steel%20duct.png)

/class%201%20duct%20fire%20safety.png)

/Fluoropolymer%20coated%20stainless%20steel%20application.png)

/Brightwater%20WWTP%20advanced%20wastewater%20treatment%20technologies.png)

/FRP%20duct%20fire%20at%20wastewater%20treatment%20facility.png)

/PSP%20and%20frp%20duct%20at%20Brightwater%20WWTP.png)