An Assessment of Landfilled GFRP Composite Waste

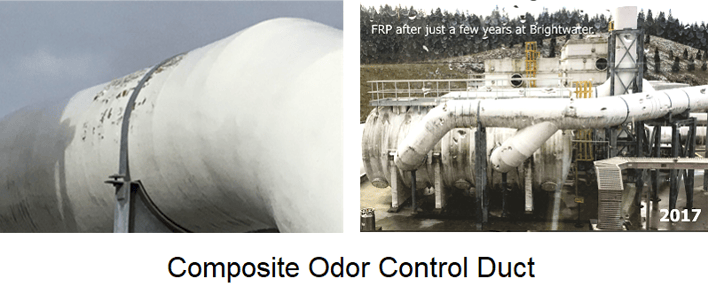

As communities, municipalities and wastewater treatment facilities alike devote more and more resources toward mitigating hydrogen sulfide gas (H2S) as an industrial and environmental pollutant [1], the resultant foul-air systems and the materials from which they are constructed must be called into question.

Historically, wastewater foul-air has been conveyed using composite materials. Composite materials generally include fiberglass reinforced plastic (GFRP), carbon (CFRP) or aramid (AFRP) reinforcing fibers dispersed in a resin matrix [2]. Based on environmental impact studies in the EU, GFRP are by far the largest group of materials in the composites industry, representing over 95% of all FRP composites [2]. Moreover, 98% of all composite waste is reported as ending up in landfills or being incinerated at end-of-life (EOL) [3].

With respect to recyclability and designing waste out, efforts to develop end-of-life options for composite waste have resulted in the exploration of chemical recycling, mechanical recycling, and pyrolysis procedures. Among these, mechanical recycling has come the closest to achieving industrial-scale market viability when compared to alternative methods. However, barriers to widespread adoption of this type of GFRP recycling persist. These can include reduced value or quality of the end product (a.k.a down-cycling), and no practical means by which to address, resolve or safely re-use industrial GFRP materials that have been chemically contaminated by process fumes or deemed hazardous waste.

With respect to recyclability and designing waste out, efforts to develop end-of-life options for composite waste have resulted in the exploration of chemical recycling, mechanical recycling, and pyrolysis procedures. Among these, mechanical recycling has come the closest to achieving industrial-scale market viability when compared to alternative methods. However, barriers to widespread adoption of this type of GFRP recycling persist. These can include reduced value or quality of the end product (a.k.a down-cycling), and no practical means by which to address, resolve or safely re-use industrial GFRP materials that have been chemically contaminated by process fumes or deemed hazardous waste.

Currently in the EU, the practices of landfilling and incinerating composite waste “will be progressively unavailable as traditional end-routes” [4]. Facing this inevitability, individuals, companies and entire industries are waking up to the costs and considerations of how to contend with end-of-life GFRP composite materials. The challenge here in the U.S. is we haven’t fully embraced the circular economy to the extent that other regions have, yet we are not far behind the EU in our need to address end-of-life options for composite waste.

Based on a report issued by the EPA, the United States generated 267.8 million tons of municipal solid waste (MSW) in 2017. More than half of that, 52% or 139.6 million tons, was landfilled. Among the landfilled solid waste, plastics represented the 2nd largest contributor at 19.2%, second only to “food which was the largest component at about 22 percent” [5].

With these considerations in mind, forward-thinking U.S. businesses and process-industries have an opportunity to get ahead of similar disposal challenges by adopting a circular economic mindset. Considering present-day industrial GFRP materials are forecast to begin entering the waste stream sometime around 2040, wastewater treatment facilities would be well-served to begin assessing the tonnage of FRP duct that can be prevented from entering U.S. landfills simply by specifying the use of fully recyclable, fully reusable coated stainless steel duct in their wastewater odor control systems.

By starting at the design phase and specifying materials which fit the circular economic model, water and wastewater treatment facilities can simultaneously set the stage for a cleaner, greener and more cost effective facility life-cycle and stand at the leading edge of a far greater environmental movement in the United States.

If you would like more information about PSP® odor control vent pipe and duct, please feel free to download our general information guide below:

OR

Visit Our Wastewater Treatment Odor Control Page

Sources:

[1] Roth S.H. (2004) Toxicological and Environmental Impacts of Hydrogen Sulfide. In: Wang R. (eds) Signal Transduction and the Gasotransmitters. Humana Press, Totowa, NJ

[2] EuCIA—European Composites Industry Association. Composites Market Report 2015: Market developments, trends, challenges and opportunities (The European GRP Market/The Global CRP Market). Available online: http://www.eucia.eu/news/composites-market-report-2015 (accessed on 9 May 2016)

[3] Halliwell, Sue (2006) End of Life Options for Composite Waste. In: National Composites Network Best Practices Guide. TWI Ltd.

[4] Ribeiro, Maria Cristina Santos et al. (2016) Recycling Approach Towards Sustainability Advance of Composite Materials’ Industry.

[5] EPA - United States Environmental Protection Agency (2017). National Overview: Facts and Figures on Materials, Wastes and Recycling. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials (accessed on 13 November 2019)