Recent Posts

Customer Installs 1st POU Chemical Blender with RMB Since Patent Grant

Topics: chemical blending, chemical blender

Patented On-Demand Adaptive In-Line-Blending and Supply of Chemical Solutions

DFS Celebrates Patent Update for innovative On-Demand In-Line Chemical Blending and Supply Technology (U.S. Patent No. 11,839,860)

Diversified Fluid Solutions is pleased to announce that it has received a new Notice of Allowance from the USPTO for US patent No. 11,839,860 for On-Demand In-Line-Blending And Supply Of Chemical Solutions. This is a continuation of U.S. application Ser. No. 17/299,927 filed Jun. 4, 2021, which is a national stage application of PCT/US2020/062458 filed Nov. 26, 2020, which claims priority to the provisional patent application U.S. App. No. 62/941,152 filed Nov. 27, 2019.

Topics: chemical blending and distribution, semiconductor manufacturing

Smarter and More Resilient Semiconductor Chemical Supply for Sustainability

On-site Generation of Ultra High Pure Ammonium Hydroxide With Reduced Environmental Impact

Karl Urquhart recently presented at the 2022 Semicon Europa, Smart and Green Manufacturing Summit in Munich, Germany. At a time when supply chain issues continue to dominate the narrative within the industry, Karl's presentation about on-site generation of semiconductor wet chemical supply directly addressed some of the foremost topics including resiliency, cost and sustainability.

DFS CELEBRATES U.S. PATENT FOR ITS ON-DEMAND IN-LINE CHEMICAL BLENDING & SUPPLY SYSTEM

Diversified Fluid Solutions is pleased to announce that it has been granted a patent from the USPTO for its innovative On-Demand In-Line Chemical Blending and Supply System (U.S. Patent No. 11,318,431). Congratulations to the DFS team of inventors named on the patent, Darren Willey, Karl Urquhart, Joseph Watters and Chris Donelson.

USER-FRIENDLY, FULLY PORTABLE AND FULLY AUTOMATED MOBILE CHEMICAL DISPENSE UNIT

The compact DFS Mobile Dispense Unit (MDU) uses two pneumatic pumps (with auto-switchover) to draw chemical from two external vessels. The system uses the tote/drum connection head, pumps, and inline filter housings to deliver chemical through the supply line to production. Pre and Post-filter pressure transducers are utilized to track filter loading and performance.

Topics: chemical distribution

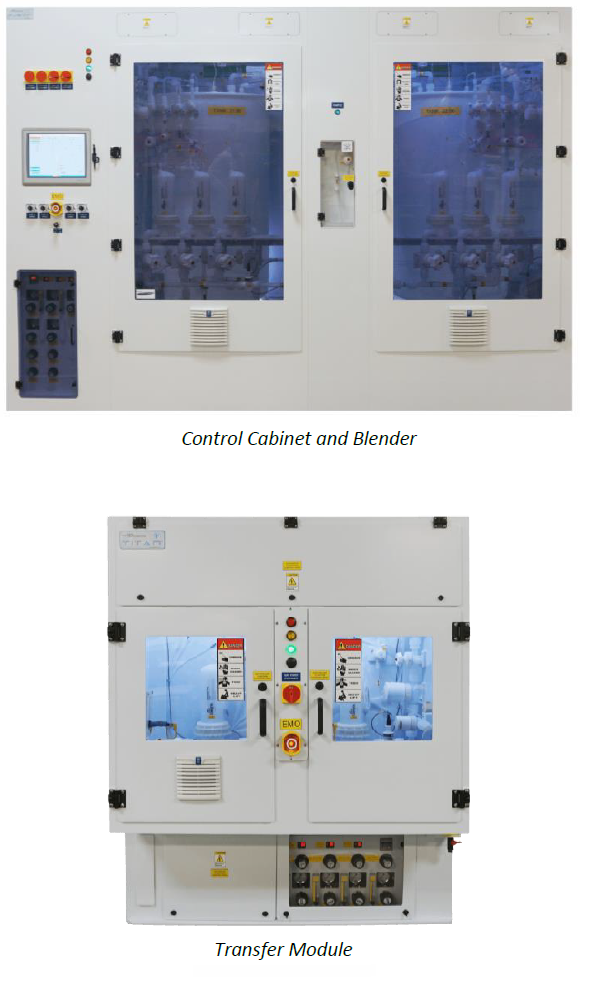

DFS Slurry Blender and Distribution System with Transfer Unit

Maximize Blend Accuracy and Production Uptime

This DFS system consists of a Slurry Blender and Distribution system, an external Transfer unit, and a Control Cabinet that controls all units. The Blender receives customer-supplied chemical from the Transfer unit or bulk feed system and facility UPW, performing a blend to tanks inside of the system. Each blend is weight-monitored and can be tracked with flow meters to ensure accuracy.

Topics: chemical blending, chemical distribution

Immersion Photolithography ASML Scanners UPW Conditioning System

Fully Automated, Space-Saving Immersion ASML Scanners UPW Conditioning System Affords Flexibility and Low Cost of Ownership

The DFS Fusion™ UPW Conditioning System provides immersion lithography ASML scanners with an uninterrupted flow of filtered ultrapure water at extremely stable flow, pressure, and temperature. The system uses maglev pumps, pressure transducers, filters, Teflon heat exchangers, and precision proportional flow control valves (PFCV) for closed loop control of the process. Built-in metrology options monitor and alarm for any conditions that are out of specification.

Topics: ultrapure water

CMP Slurry Blending with Closed-Loop Real-Time Control & Monitoring

Remove Expensive Labor-Intensive Offline Metrologies and Manual Process Adjustments

DFS recently completed a process characterization and successfully developed onboard control technology that allows for closed-loop control of a customer-specific semiconductor cmp slurry solution in a blend and distribution operation.

Topics: process control, chemical mechanical planarization, chemical blending, chemical blender

DFS Titan™ Transfer and Offload Bulk Chemical Distribution System

Bulk Chemical Distribution

The DFS Titan™ Transfer and Offload System automatically transfers an aqueous chemical from the tanker offload cabinet to the main distribution tanks. This system monitors the level of the main bulk tanks and allows tanker offload into storage tank A. Storage tank A refills tank B at the defined setpoint, and all chemical transfers for production tools come from storage tank B.

Topics: chemical distribution

DFS Titan™ Dual Vessel CDU Enables A Continuous Chemical Supply with Closed Loop Pressure Control

The DFS Titan™ Dual Vessel CDU transfers from interchangeable vessels via AODD pumps. The system maintains continuous chemical pressure to production areas using either automated closed loop pressure control or deadhead supply.

Topics: chemical distribution

DFS and GEMU Collaborate on PPT Level Ultra High Purity Ammonium Hydroxide Blender

Gemu and DFS Collaborate on UHP Reliable Systems to Produce <10ppt Ammonium Hydroxide (NH4OH) On Site

The Diversified Fluid Solutions (DFS) on-demand blending system produces high purity ammonium hydroxide (NH4OH), which is a combination of ammonia gas (NH3) and high purity water.

DFS systems produce ultra high purity (UHP) chemical blends with impurity levels below the 10 ppt detection limit, which leads to a high level of process reliability.

Topics: process control, chemical blending, ammonium hydroxide generation

DFS Fusion™ MCBS+

The DFS Fusion™ MCBS+ blends slurries or aqueous chemicals through our inline On-Demand™ blend technology or by weight and volume. All blending methods receive chemical from the customer-supplied chemical source, UPW, or on-board vessels.

Blends are prepared in either of the two 114L blend and dispense tanks, and each blend is verified through the blend specific on-board metrology set. The system maintains and supplies constant temperature and pressure control to the production area tools. Maglev pumps (one per tank) are used for the main chemical supply, and pneumatic pumps are used for blend recirculation and transfer from external vessels.

Topics: process control, chemical blending

Fusion™ MCBS: A Closer Look

The DFS Fusion™ MCBS is a mobile chemical blending platform that can feed up to three production tools. The MCBS blends chemical by weight or by volume from externally connected source vessels, house ultrapure water (UPW), and optional house-supplied chemical.

Blends are verified through the on-board metrology in the blend tank and then transferred to the day tank maintaining constant temperature and pressure-controlled supply to the production areas. The MCBS uses a single centrifugal pump for the main chemical supply and pneumatic pumps for blend recirculation and transfer from the external vessels.

Topics: process control, chemical blending

High Purity Nitrogen Pressure Control and Filtration Bulk Gas Skid

DFS High Purity NITROGEN (HPN2) BULK GAS SKID

The DFS High Purity Nitrogen (HPN2) Pressure Control and Filtration Skid enables pressure regulation and particle capture between large facility purifiers and semiconductor fab distribution. The compact design of this system minimizes gas pad or purifier room space required, while preserving ergonomic operation and maintenance access. Pre-engineered options practically eliminate design time, minimize lead-times, and reduce installation cost and schedule. Our Utility Nitrogen Bulk Gas systems are configurable to customer’s needs from field-proven base designs. DFS Bulk Gas Equipment is delivered as a complete factory-tested packaged system.

Topics: process control, gas systems

Utility Nitrogen Pressure Control and Filtration Bulk Gas Skid

DFS Utility NITROGEN (UN2) BULK GAS SKID

The DFS Utility Nitrogen (UN2) Pressure Control and Filtration Skid enables pressure regulation and particle capture between bulk Nitrogen source and semiconductor fab distribution. The compact design of this system minimizes gas pad or purifier room space required, while preserving ergonomic operation and maintenance access. Pre-engineered options practically eliminate design time, minimize lead-times, and reduce installation cost and schedule. Our Utility Nitrogen Bulk Gas systems are configurable to customer’s needs from field-proven base designs.

Topics: gas systems

A CLOSER LOOK AT DFS' HIGH PURITY NITROGEN HPN2 BULK GAS SKID

The DFS High Purity Nitrogen (HPN2) Purifier Bypass Skid enables automatic bypass of large facility nitrogen purifiers to ensure continuity of supply to semiconductor fab distribution. This bulk gas skid is a compact design that minimizes gas pad or room purifier space. The skid is delivered as a turn-key factory-tested system.

Topics: process control, gas systems

FULLY AUTOMATED DUAL LOOP SLURRY BLENDING SYSTEM

The fully automated DFS Fusion™ Dual Loop Slurry Chemical Blender is designed to allow for blending of up to 3 Chemicals and UPW with the ability to handle additional slurry inputs if needed. This system will also inject, monitor, and maintain hydrogen peroxide concentration utilizing ultrasonic flow meters, metering valves and refractive index.

Topics: process control, chemical blending

A Closer Look at the Components of A DFS Fusion™ Modular Chemical Blender

DFS Blenders greatly reduce the floor space requirements, facilitation costs, and the total cost of ownership for blended chemistries. Process yield / improvements are a large impact area because of our blenders’ accuracy. The more on-target the chemicals are in assay; the less rework or process target adjustments have to take place in the production environment.

Topics: process control, chemical blending

DFS Announces New Fusion™ On-Demand™ Mobile Chemical Blender

Designed for one of our newest customers in New Mexico, the DFS Fusion™ On-Demand™ Mini Mix is engineered to transfer chemical from an interchangeable 5 gallon Pail and bulk supply to the internal On-Demand Blender.

Chemical 1 is supplied via the internal vessel. UPW, and Chemical 2 are supplied via the house supply source.

Topics: process control, chemical blending

DFS ACvFLO™ Gas Delivery Systems Set a new standard in Gas Cabinet Technology

To serve today’s Semiconductor gas market; DFS employs advanced technical knowledge, build capacity, and programming expertise to develop game-changing gas delivery systems.

The ACvFLO™ High Purity Gas Cabinet System has advanced functionality and capabilities not seen in the Semiconductor industry to date.

These advancements include an open, fully integrated PLC and HMI panel, with connectivity and networkability, operational sequences, and automated pressure control.

Topics: process control, gas systems

/DFS%20RMB%20System%201.png)

/featured-image-patent-diagram.png)

/POU.gif)

/mobile-chemical-dispense-unit-mdu.png)

/ultrapure-water-upw-conditioning-system.png)

/dfs-fusion-chemical-blender.gif)

/DFS-Titan-Transfer-and-Offload-System.png)

/chemical-distribution-unit-titan-dual-vessel.gif)

/DFS-GEMU-UHP-System.png)

/DFS-Mobile-Chemical-Blending-System-Plus-1.png)

/mobile-chemical-blending-system.png)

/high-purity-nitrogen-bulk-gas-skid.png)

/DFS%20UN2%20Graphic.png)

/DFS%20High%20Purity%20HPN2%20Bulk%20Gas%20Skid.png)

/Dual%20Loop%20Slurry%20Chemical%20Blender_front.png)

/DFS%20Fusion%20Modular%20Chemical%20Blender.png)

/Fusion%20On-Demand%20Mobile%20Chemical%20Blender.jpg)

/DFS%20Gas%20Delivery%20Systems%20come%20integrated%20with%20advanced%20HMI%20capabilities.png)