Customer Installs 1st POU Chemical Blender with RMB Since Patent Grant

Topics: chemical blending, chemical blender

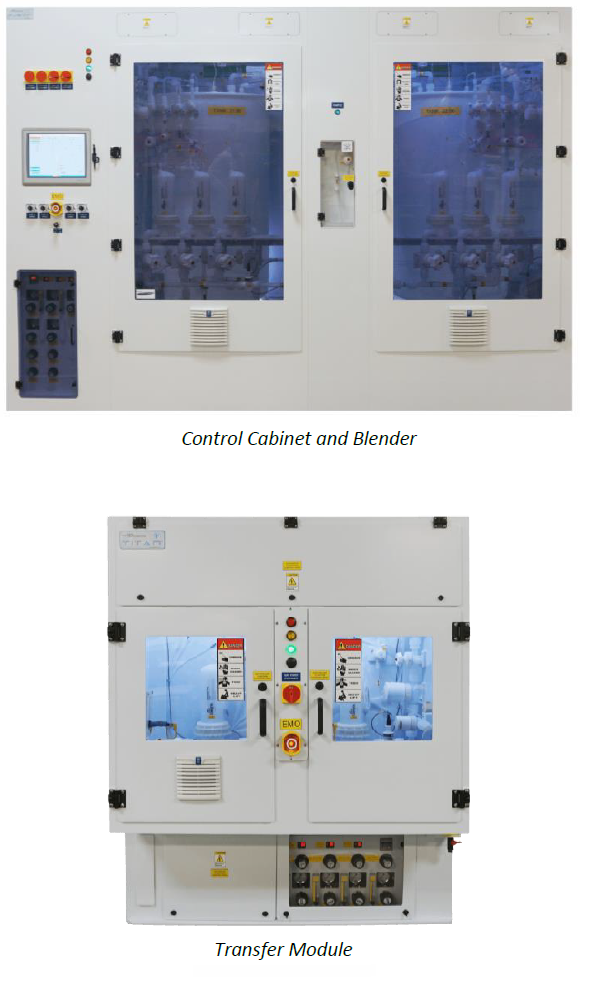

DFS Slurry Blender and Distribution System with Transfer Unit

Maximize Blend Accuracy and Production Uptime

This DFS system consists of a Slurry Blender and Distribution system, an external Transfer unit, and a Control Cabinet that controls all units. The Blender receives customer-supplied chemical from the Transfer unit or bulk feed system and facility UPW, performing a blend to tanks inside of the system. Each blend is weight-monitored and can be tracked with flow meters to ensure accuracy.

Topics: chemical blending, chemical distribution

CMP Slurry Blending with Closed-Loop Real-Time Control & Monitoring

Remove Expensive Labor-Intensive Offline Metrologies and Manual Process Adjustments

DFS recently completed a process characterization and successfully developed onboard control technology that allows for closed-loop control of a customer-specific semiconductor cmp slurry solution in a blend and distribution operation.

Topics: process control, chemical mechanical planarization, chemical blending, chemical blender

Product Spotlight: DFS Fusion™ RMB Chemical Blender

5 Advantages of the New DFS Fusion™ RMB Blender

DFS’s new patent pending Fusion™ RMB Blender is an active and reverse calculating mass balance system that is overall less equipment, at a lower cost, with improved flexibility and trending features.

Topics: process control, chemical blending

DFS and GEMU Collaborate on PPT Level Ultra High Purity Ammonium Hydroxide Blender

Gemu and DFS Collaborate on UHP Reliable Systems to Produce <10ppt Ammonium Hydroxide (NH4OH) On Site

The Diversified Fluid Solutions (DFS) on-demand blending system produces high purity ammonium hydroxide (NH4OH), which is a combination of ammonia gas (NH3) and high purity water.

DFS systems produce ultra high purity (UHP) chemical blends with impurity levels below the 10 ppt detection limit, which leads to a high level of process reliability.

Topics: process control, chemical blending, ammonium hydroxide generation

DFS Fusion™ MCBS+

The DFS Fusion™ MCBS+ blends slurries or aqueous chemicals through our inline On-Demand™ blend technology or by weight and volume. All blending methods receive chemical from the customer-supplied chemical source, UPW, or on-board vessels.

Blends are prepared in either of the two 114L blend and dispense tanks, and each blend is verified through the blend specific on-board metrology set. The system maintains and supplies constant temperature and pressure control to the production area tools. Maglev pumps (one per tank) are used for the main chemical supply, and pneumatic pumps are used for blend recirculation and transfer from external vessels.

Topics: process control, chemical blending

Fusion™ MCBS: A Closer Look

The DFS Fusion™ MCBS is a mobile chemical blending platform that can feed up to three production tools. The MCBS blends chemical by weight or by volume from externally connected source vessels, house ultrapure water (UPW), and optional house-supplied chemical.

Blends are verified through the on-board metrology in the blend tank and then transferred to the day tank maintaining constant temperature and pressure-controlled supply to the production areas. The MCBS uses a single centrifugal pump for the main chemical supply and pneumatic pumps for blend recirculation and transfer from the external vessels.

Topics: process control, chemical blending

Reduce Contamination Risk, Produce UHP NH4OH On-Site

In our semiconductor manufacturing industry, everyone is constantly trying to save money and space when and where they can.

This usually translates to where and whom you buy your chemical supplies and equipment.

This is done with a major focus on the least amount of risk exposure possible.

Topics: process control, chemical blending

FULLY AUTOMATED DUAL LOOP SLURRY BLENDING SYSTEM

The fully automated DFS Fusion™ Dual Loop Slurry Chemical Blender is designed to allow for blending of up to 3 Chemicals and UPW with the ability to handle additional slurry inputs if needed. This system will also inject, monitor, and maintain hydrogen peroxide concentration utilizing ultrasonic flow meters, metering valves and refractive index.

Topics: process control, chemical blending

A Closer Look at the Components of A DFS Fusion™ Modular Chemical Blender

DFS Blenders greatly reduce the floor space requirements, facilitation costs, and the total cost of ownership for blended chemistries. Process yield / improvements are a large impact area because of our blenders’ accuracy. The more on-target the chemicals are in assay; the less rework or process target adjustments have to take place in the production environment.

Topics: process control, chemical blending

DFS Announces New Fusion™ On-Demand™ Mobile Chemical Blender

Designed for one of our newest customers in New Mexico, the DFS Fusion™ On-Demand™ Mini Mix is engineered to transfer chemical from an interchangeable 5 gallon Pail and bulk supply to the internal On-Demand Blender.

Chemical 1 is supplied via the internal vessel. UPW, and Chemical 2 are supplied via the house supply source.

Topics: process control, chemical blending

Versatile On-Demand Chemical Blender is a Big Hit with Semiconductor Manufacturer

DFS recently developed and released a compact SC-1, 3 part blender, for a large Semiconductor Manufacturer. The Standard Clean Solution #1 (SC-1) process involves a sequence of cleaning steps using “standard” solutions and employs a mixture of ammonium hydroxide (NH4OH), hydrogen peroxide (H2O2), and DI water (H2O). The system enables recipe customization through an HMI with verified authorization.

Topics: process control, chemical blending

On-site Chemical Blending Increases Overall IC Process Yield, When Done Right.

Precise control of chemical composition through use of on-site chemical blending and mixing systems improves overall IC process yield.

This is accomplished by providing more consistent quality of materials that come into contact with the wafer and its forming circuits.

On-site blending results in tighter assay control, higher purity, and lower particles. On-site blenders also allow users to test materials suppliers for comparison to optimize ROI and control cost.

Topics: process control, chemical blending

Mobile Chemical Blending Systems (MCBS) Help Overcome the Challenges of Next-Generation Chemicals

Uses and Benefits of Mobile Chemical Blending Systems (MCBS)

A given factory's chemical formulations are pushed to: 1) improve affordability, while 2) requiring higher process performances in critical areas. One way to accomplish both goals is to target incoming chemical solutions that are high in concentrations and complexity.

Achieving the proper dilution and high performance in current and upcoming process nodes requires complex blends of organic and inorganic compounds in CMP slurry formulations. The combinations of all these factors result in products that have nuanced mixing and handling requirements.

Topics: process control, chemical blending

Chemical Blend Uniformity and Semiconductor Process Yield

Characterization and importance of chemical mix uniformity, precision, and preservation of purity levels to reduce cost, prevent rework/scrap, and increase Process yield overall.

Manufacturers place a great deal of emphasis on cost reduction, prevention of rework or scrap, and increasing overall process yield. One result has been a rise in precision and control technology innovations geared towards process chemicals uniformity.

Many focus on individual aspects of metrology for quantitative, or qualitative determination, either by off-line or inline methods, with the intent to achieve the highest productivity at the lowest cost.

Topics: process control, chemical blending

Preparing a DFS High-Purity CMP Slurry Blender For Delivery

Diversified Fluid Solutions recently completed work on a precision slurry blender which increases overall production capacity and process control.

Through advancements in our proprietary blending technology, the fully-automated Fusion™ Slurry Blender eliminates deadlegs in the flow path of the slurry while managing loop pressure control to +/- 0.3 psi.

The end result is improved yields, process control and repeatability across the board.

Topics: process control, chemical blending

/DFS%20RMB%20System%201.png)

/dfs-fusion-chemical-blender.gif)

/dfs-fusion-rmb-blender-open.jpg)

/DFS-GEMU-UHP-System.png)

/DFS-Mobile-Chemical-Blending-System-Plus-1.png)

/mobile-chemical-blending-system.png)

/NH4OH%20Fusion%20Chemical%20Blending%20System.jpg)

/Dual%20Loop%20Slurry%20Chemical%20Blender_front.png)

/DFS%20Fusion%20Modular%20Chemical%20Blender.png)

/Fusion%20On-Demand%20Mobile%20Chemical%20Blender.jpg)

/Integrated%20Circuit%20IC%20Manufacturing.png)

.png)

/Fusion%20Chemical%20Blender.png)

/DFS%20Slurry%20Blender%204.png)