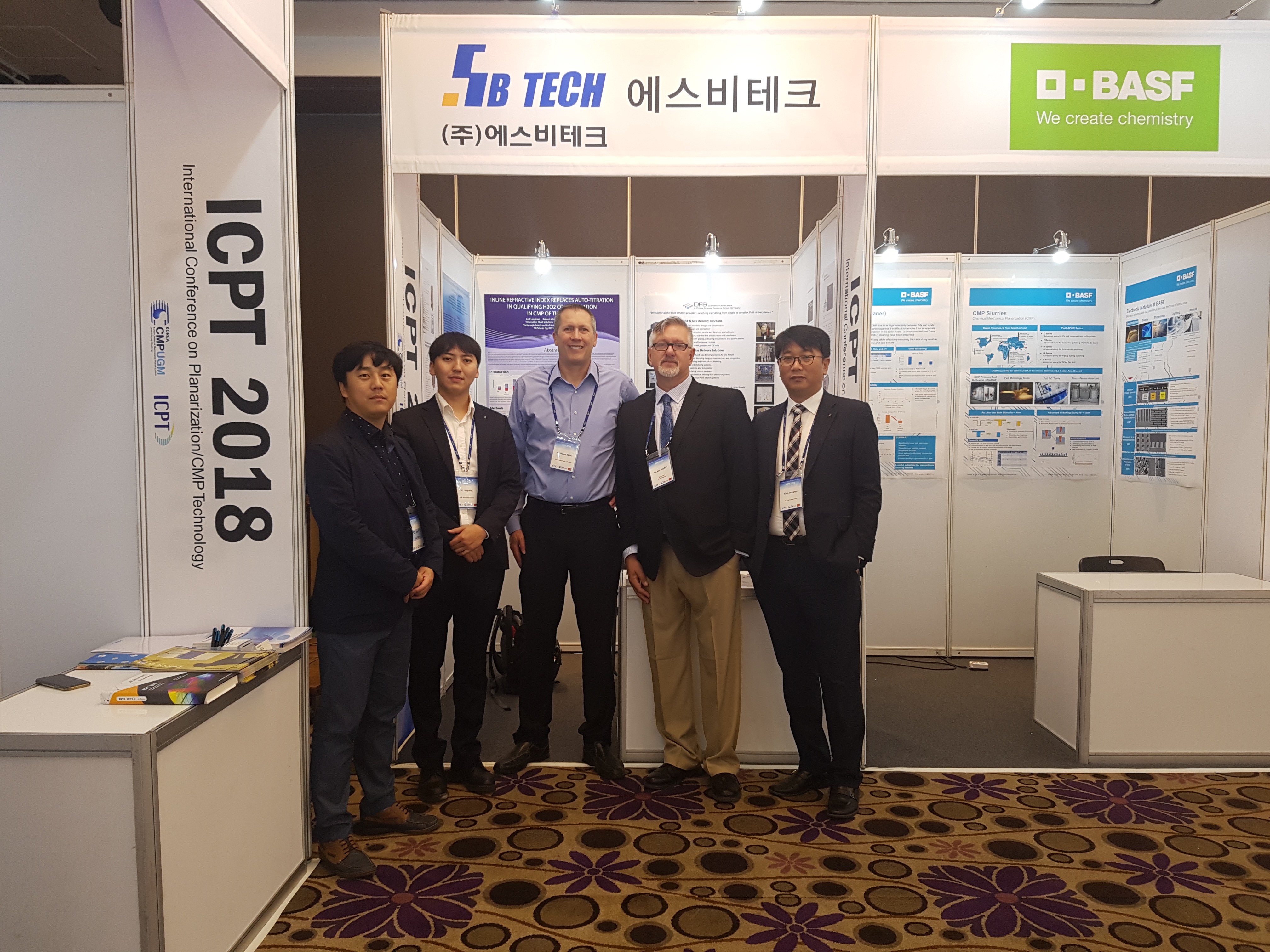

Highlights From the International Conference On Planarization/CMP Technology (ICPT)

Karl Urquhart and our Korea licensee SB-TECH present Real Time Process Monitoring in CMP, Post CMP Clean Blending and Distribution Applications at the ICPT 2018, October, 15-17, 2018, Seoul, Republic of Korea.

Read More

Topics: process control, chemical mechanical planarization

Versatile On-Demand Chemical Blender is a Big Hit with Semiconductor Manufacturer

DFS recently developed and released a compact SC-1, 3 part blender, for a large Semiconductor Manufacturer. The Standard Clean Solution #1 (SC-1) process involves a sequence of cleaning steps using “standard” solutions and employs a mixture of ammonium hydroxide (NH4OH), hydrogen peroxide (H2O2), and DI water (H2O). The system enables recipe customization through an HMI with verified authorization.

Read More

Topics: process control, chemical blending

Employees Enjoy a Paid Afternoon of Fun in the Peerless Idaho Sun

DFS is growing our business supplying liquid and gas systems. Our success is made possible through the hard work, commitment, and dedication of our employees. To celebrate, we held a summer employee barbecue in Kleiner Park in Meridian.

Great food and fun...water balloon fights, pinata, bean-bag-toss competitions, face painting and more. See the hightlights below. Great time in perfect Idaho weather. Come join our team https://www.cpsgrp.com/careers.php.

Read More

Topics: careers

*Eric Peterson is a Sr. Mechanical Engineer at Diversified Fluid Solutions and parent to an active Meridian, Idaho Eagle Scout troop member.

A Trail of Good Deeds and Service

My son Cameron from BSA Troop 28 in Meridian recently completed his Eagle Scout Project by relocating and/or repairing most of the nature trail signs for Lucky Peak Nursery.

Lucky Peak Nursery is part of the U.S. Forest Service where they harvest and preserve seeds, then grow trees and shrubs to replant after disasters.

Read More

Topics: public service, careers

Precise control of chemical composition through use of on-site chemical blending and mixing systems improves overall IC process yield.

This is accomplished by providing more consistent quality of materials that come into contact with the wafer and its forming circuits.

On-site blending results in tighter assay control, higher purity, and lower particles. On-site blenders also allow users to test materials suppliers for comparison to optimize ROI and control cost.

Read More

Topics: process control, chemical blending

Uses and Benefits of Mobile Chemical Blending Systems (MCBS)

A given factory's chemical formulations are pushed to: 1) improve affordability, while 2) requiring higher process performances in critical areas. One way to accomplish both goals is to target incoming chemical solutions that are high in concentrations and complexity.

Achieving the proper dilution and high performance in current and upcoming process nodes requires complex blends of organic and inorganic compounds in CMP slurry formulations. The combinations of all these factors result in products that have nuanced mixing and handling requirements.

Read More

Topics: process control, chemical blending

Precise Slurry Requirements Increase CMP Process Windows but Necessitate greater dependence on Inline Metrology

Chemical Mechanical Planarization or Polishing (CMP) is the method of using chemical slurry formulations with mechanical polishing-pad-action to flatten conductive or dielectric materials on silicon wafers in semiconductor manufacturing.

The end goal is to achieve a flat enough surface aspect ratio as required by photolithography steps, where layers of integrated circuits are layered step by step.

Read More

Topics: process control, chemical mechanical planarization

Characterization and importance of chemical mix uniformity, precision, and preservation of purity levels to reduce cost, prevent rework/scrap, and increase Process yield overall.

Manufacturers place a great deal of emphasis on cost reduction, prevention of rework or scrap, and increasing overall process yield. One result has been a rise in precision and control technology innovations geared towards process chemicals uniformity.

Many focus on individual aspects of metrology for quantitative, or qualitative determination, either by off-line or inline methods, with the intent to achieve the highest productivity at the lowest cost.

Read More

Topics: process control, chemical blending

DFS ACvFLO™ Gas Delivery Systems Set a new standard in Gas Cabinet Technology

To serve today’s Semiconductor gas market; DFS employs advanced technical knowledge, build capacity, and programming expertise to develop game-changing gas delivery systems.

The ACvFLO™ High Purity Gas Cabinet System has advanced functionality and capabilities not seen in the Semiconductor industry to date.

These advancements include an open, fully integrated PLC and HMI panel, with connectivity and networkability, operational sequences, and automated pressure control.

Read More

Topics: process control, gas systems

Highlights From DFS' 2018 Semicon Korea Debut

Diversified Fluid Solutions recently kicked-off its presence in South Korea by attending and exhibiting at the 30th annual Semicon Korea expo in Seoul.

The exhibition featured nearly 2,000 booths from global leaders in the semiconductor industry and drew an estimated total of 50,000 attendees to the event.

On display from DFS was this Fusion MCBS Minimix unit (shown to the right) as well as a multitude of other precision chemical and gas blending and distribution systems.

Read More

Topics: semicon

In Recognition of Susan's Countless Contributions

Employees of Diversified Fluid Solutions recently gathered to wish Susan Elsey, one of the company’s first employees, a fond farewell.

Susan, wife of CEO Fred Elsey, helped found the company in 2009 along with Fred Elsey and Darren Willey. Over the years, Susan has worked in accounting, human resources, inside sales, graphic design and just about every other role needed to keep the company going.

Read More

Topics: careers

DFS Uses Custom Metal Fabrication Expertise To Develop Electrician Training Table

Part of what comes with specializing in the development of high-purity-high-precision systems is a talented pool of intelligence capable of performing unique plastic and custom metal fabrication projects.

In fact, it's not uncommon for us to recieve requests for custom products like this multi-functional electricians training table.

Given Diversified Fluid Solutions' commitment to schedule, technology, and service, we were thrilled to be presented with an opportunity to combine our experience and standards into an educational product.

Read More

Topics: public service, careers

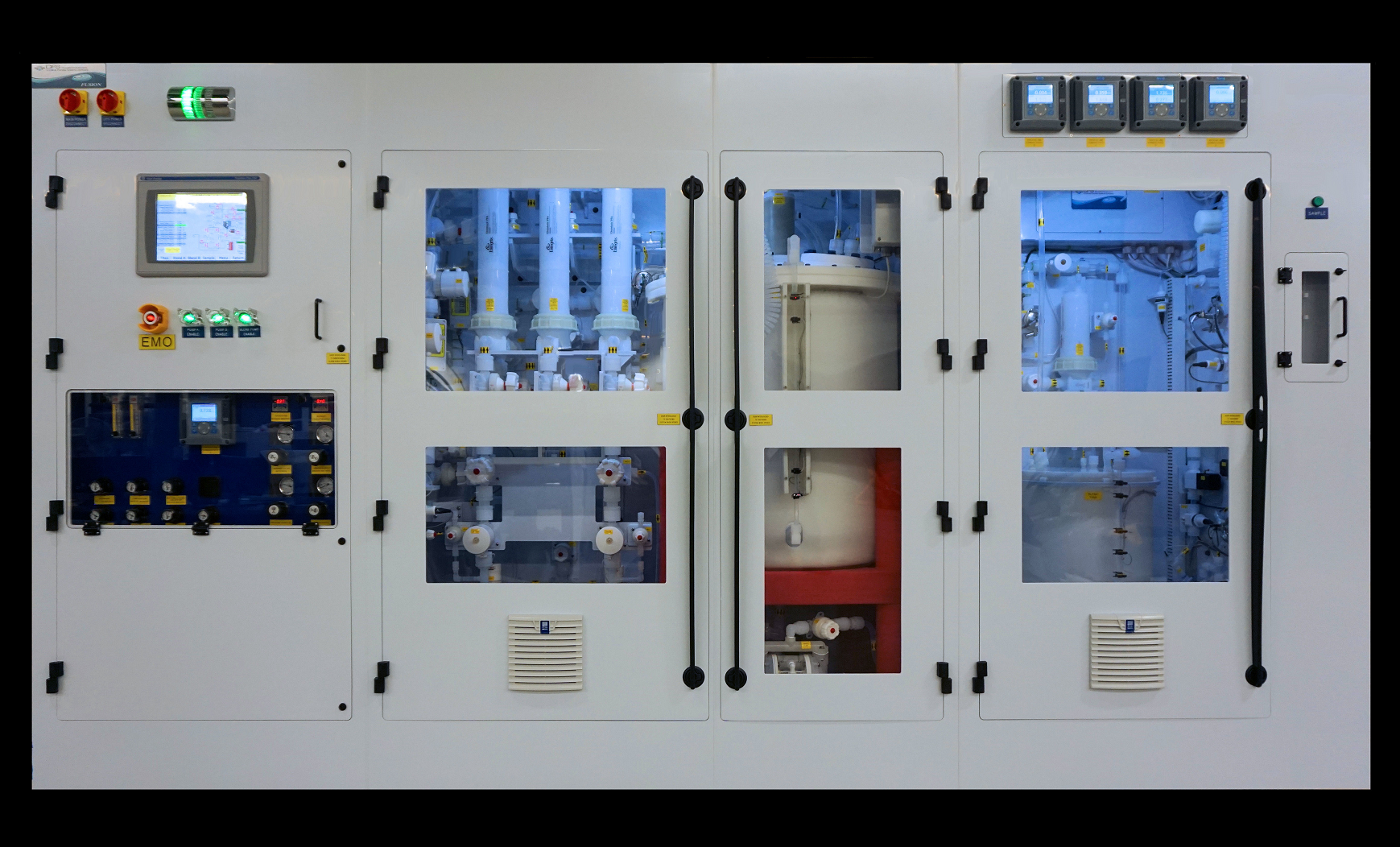

Preparing a DFS High-Purity CMP Slurry Blender For Delivery

Diversified Fluid Solutions recently completed work on a precision slurry blender which increases overall production capacity and process control.

Through advancements in our proprietary blending technology, the fully-automated Fusion™ Slurry Blender eliminates deadlegs in the flow path of the slurry while managing loop pressure control to +/- 0.3 psi.

The end result is improved yields, process control and repeatability across the board.

Read More

Topics: process control, chemical blending

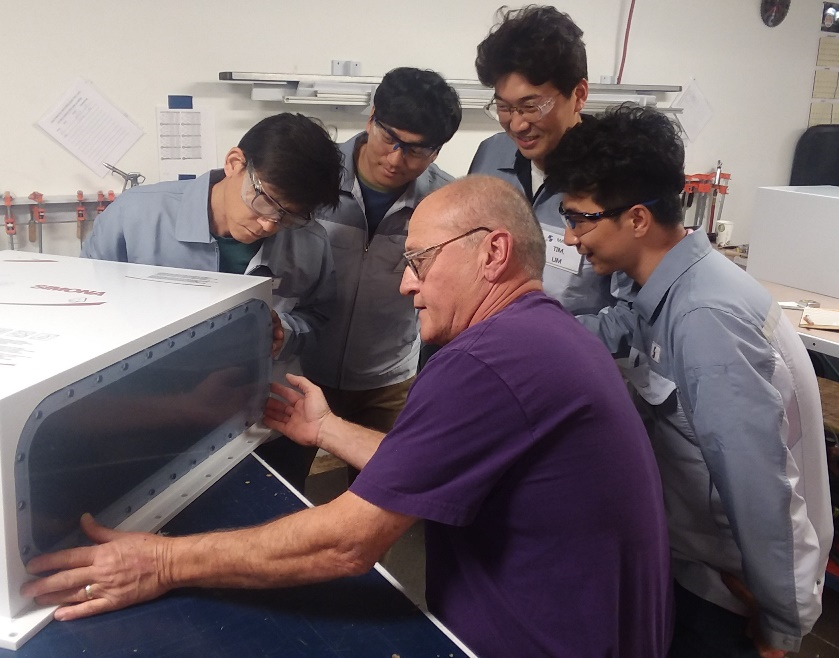

During the month of September, Diversified Fluid Solutions (DFS) of Boise, Idaho hosted a delegation of Korean technicians from SEBO Corp, (SEBO), a leading contractor and manufacturer in Korea.

DFS designs and manufactures high-purity chemical, gas and slurry blending and distribution systems for high tech customers worldwide. DFS recently licensed SEBO to manufacture DFS blending and distribution systems for certain Asian semiconductor markets. SEBO is currently building a state of the art factory in Korea to manufacture the systems.

Read More

Topics: chemical blending, gas systems

In Recognition of Paul Lyons - DFS Fluid Management Systems Engineer

Paul Lyons, one of the first employees of Diversified Fluid Solutions, has left the company to take an engineering position elsewhere.

"Paul was a critical contributor in building DFS to where it is today, due to his knowledge, technical skill and passion for creating the best fluid blending and distribution systems possible," said Fred Elsey, CEO of DFS. "Paul's dedication started when we were just getting off the ground and he has been a key factor in making DFS a leading supplier of advanced fluid management systems to the semiconductor industry."

Read More

Topics: chemical blending, careers, gas systems