Celebrating first joint-effort between Exyte Services and Airgard for a commissioning project

Airgard is pleased to announce that we have successfully completed our first joint effort with Exyte Services to commission an Airgard system for a key client in Singapore. The commissioning involved a used scrubber system that was moved from one fab to another to replace an old epi scrubber that needed to be removed and scrapped. Prior to the move-in and installation, the Airgard unit was flushed and cleaned. Once the system was positioned and tied into utilities, the Exyte Services and Airgard FSE team were able to perform a thorough commissioning and start-up.

As part of the commissioning and start-up process, factory-trained professionals from both Exyte Services and Airgard carried out a full system inspection including (but not limited to):

- leak tests

- pneumatic valve check and replacement

- couplings check and tightening

- set inlet water flow rate

- inlet pressure zeroing

- pump rotation check

- N2 purge

- scrubber mount check and seismic restraint verification

- water, N2, drain and power check

- control box wiring inspection

- inlet plunger assembly inspection and verification

- system power-on

- set N2 pressure and flow

- check all HMI parameters

- test low-level and high-level water switch

- check fault alarms

- inlet flow fault

- pump flow fault

- pump fail fault

- N2 flow fault

- city water flow fault

- test system standby

- run cycle gas

- tool on production mode and ongoing monitoring

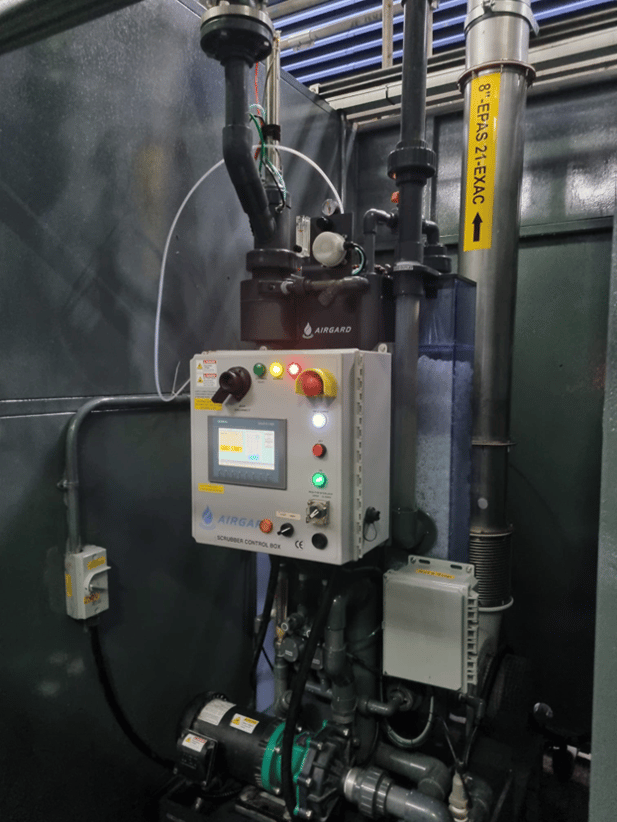

Scrubber positioned and utilities tied-in – ready for commissioning

James (Exyte Services) in action - trained through Airgard's factory certified program

Ultimately, this project presented a perfect opportunity to collaborate and share expertise among our sister and parent companies. Airgard would like to thank all the team members who were involved and made this effort a success!

.gif?width=305&height=72&name=Logo%20AIRGARD%20wht%20txt%20on%20trans%20(1).gif)